Every industry has its own terminology and language designed to help technicians, engineers, practitioners and really, anyone working in a specialized industry, to communicate effectively. You’ll hear auto mechanics talk about clearances, torque, fuel ratios, etc., while doctors use terms such as, Epistaxis (nose bleed), pharyngitis (sore throat), pyrexia and febrile response (fever) in discussing conditions among colleagues. The problem comes when they are not able to put these terms into understandable sentences for us, the uninitiated.

So let’s take a look at the traditional heating and air conditioning system and try and break it down so that when that technician starts to tell you what may be wrong with it, you can keep up. First we’ll take a look at how the system operates in general, and then we’ll look at specific parts that will commonly break down and need replacing.

How it works

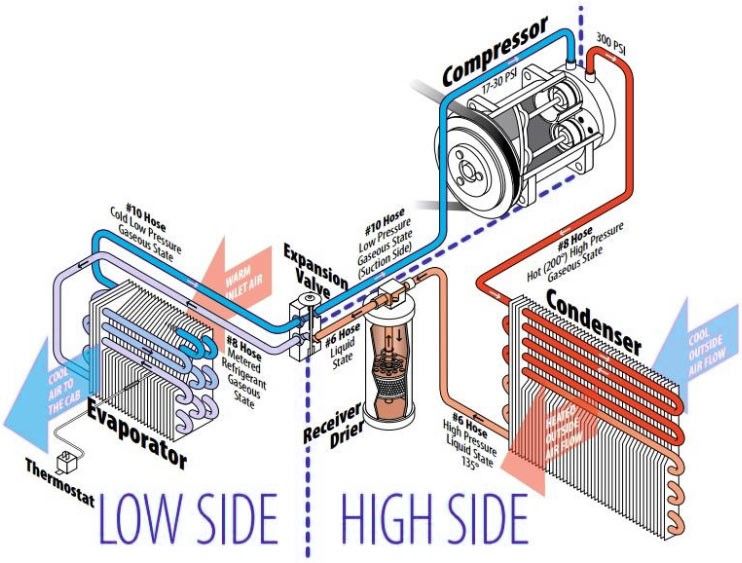

It all starts with the compressor in the big box outside called the condenser (we’ll talk about that in a minute). When the compressor is running it pulls the hot refrigerant (Freon) gas into itself. Here is where it acts like a garbage compactor pressing the molecules of the refrigerant together. This causes the gas to get hotter and build pressure. This hot, high pressure gas is then released into the heat exchanger (think car radiator). If you look behind the grill covers on that box outside (the condenser) you’ll see a wall of small fins or veins. Those fins are attached to a long tube that is looped back and forth carrying the pressurized gas from the compressor (see illustration high side below). This is where the gas gets converted to a liquid. When the fan on top of the box is on, it draws air through the fins transferring the heat from the hot refrigerant to the outside air which is then carried up and out cooling the refrigerant. When the gas is cooled it converts to a cold liquid which is then pushed up to the next stage, the evaporator coils. The coil is a smaller version of the heat exchanger outside, but it does the same thing. This is where the warm air from the house is pushed across the cold coils and the heat from the air is transferred to the refrigerant making the air cooler (see illustration low side). The cooler air is then sent out to the different rooms in your house through a duct system. As the liquid refrigerant heats up it returns to a gas and is pulled back down to the compressor to start the cycle over again.

Now that we have a basic understanding of how this thing works, let’s look at the more common things that can go out on your unit prompting that service call.

The capacitor: The common capacitor found in the AC system is called a running capacitor. As the name implies this piece of equipment helps the compressor and the fan motors to run smoothly. They are small little batteries that help keep the current, used to operate the motors, smooth. The smoother the current, the smoother the motors run, which means they will operate more efficiently and last longer.

Contactors: These are used to connect the electrical current to the machine by opening and closing. When closed the contacts come together allowing the current to flow to the machine. As the temperature in the house reaches the setting on the thermostat, the contacts open interrupting the current to the motor, turning it off.

These two items are extremely important for the efficiency of your unit. It is important that these items stay in good working order since they increase the longevity of your system. The main reason for the wear and breakdown of these parts is due to lack of cleaning of the coils listed above. If air can’t freely flow through these coils, temperatures begin to rise, which causes the capacitor and contacts to over work. This will result in the failure of these parts and damage to the motors (two fan motors and the compressor).

Fans: These are not difficult to understand, they’re fans. They are comprised of basically two parts, the motor and the blades. When the AC unit comes on, one fan pushes air through the cold evaporator coil, then throughout the house via ducts. The second fan pulls air through the hot condenser coils, as discussed earlier. They work just like any other fan in your house and like those fans they will get dirty. As dirt builds they get bogged down and out of balance, this creates uneven wear in the motor and overheating. You end up with a noisy unit and eventual breakdown needing replacement. So it is important to keep them clean by changing the filters regularly and washing down the condenser about twice a year.

There are quite a few more parts involved with the operation of your AC unit, and they all require regular maintenance in order to insure the best efficiency and a longer life. This is a good reason to speak to one of our service technicians, or the office, about the Club Membership we offer at Bitter Heating and Air Conditioning. As a member you get two free cleanings along with performance tune-ups, making sure you get the best performance your system was designed to give. Call us, sign up and feel confidant your AC system is working its best.